Features:

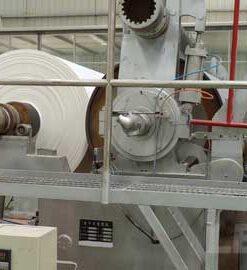

Papermaking wastewater refers to wastewater generated during the pulping and papermaking process. Including pulping and cooking waste liquid, washing waste water, bleaching waste water and paper machine white water. Papermaking wastewater has complex composition and poor biodegradability, which is difficult to treat industrial wastewater. my country’s paper industry mostly uses straw and wood pulp as raw materials for papermaking. Pulp and paper production generally consist of pulping, pulp washing, bleaching, and papermaking processes. The pulping in the paper industry includes alkaline pulping, chemical mechanical pulping and mechanical pulping. According to different pulping methods, different raw materials, different pulp yields, different papermaking varieties, and the presence or absence of chemical recycling, the occurrence and discharge of pollutants are very different, but they basically contain a large amount of suspended matter and BOD, COD and some toxic substances are usually treated by a combination of physical and chemical methods and biological methods.

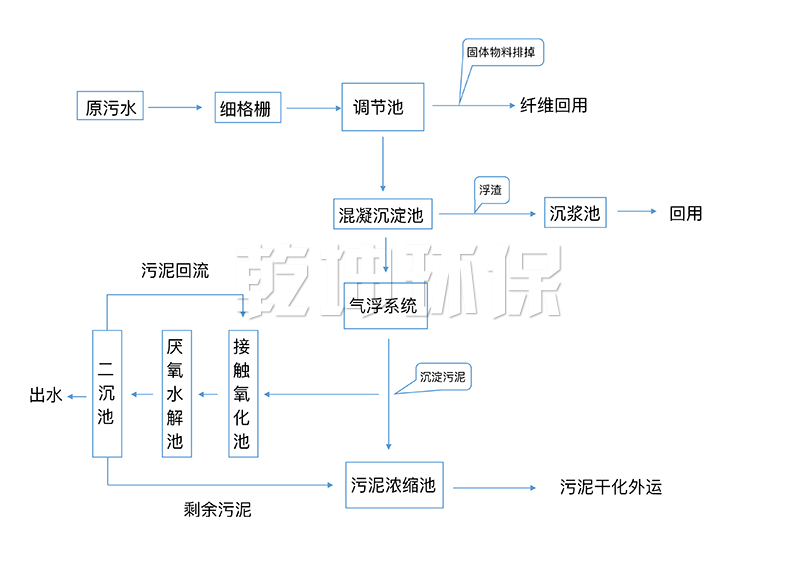

Processing steps:

Pretreatment: Waste water from the papermaking production line is first passed through the inclined grid to filter and remove some fine fiber materials;

Quenching and tempering treatment: the pre-treated wastewater is an automatic flow regulating pool to adjust the water quality concentration and make the water volume uniform;

Scum treatment: the waste water after quenching and tempering treatment is lifted by the pump*** air flotation equipment, the air flotation equipment removes the scum of the wastewater;

Biochemical treatment: The wastewater after scum treatment is biochemically treated to remove a large amount of remaining organic matter in the wastewater;

Discharge up to standard: After the water quality index of the wastewater meets the discharge requirements, it will be discharged.

Reviews

There are no reviews yet.